Drive innovation with 3D Laser texturing on medical implants

As an implant manufacturer, have you ever wondered how to make your distinctive mark in this business? 3D Laser texturing raises titanium implant surface quality and lowers manufacturing costs.

When it comes to texturing titanium implants’ surfaces to improve osseointegration or, as research seems to indicate, anti-bacterial properties, we can substitute the traditional manufacturing process and its manual operations (sandblasting and/or chemical etching) with a fully digital process. This Laser texturing process improves the part’s surface quality while allowing you to reduce your production costs and the contamination risks (Technical article).

Laser texturing on orthopedic implants: Limitless texture design possibilities

Innovation

Drive innovation with distinctive intelligent surfaces—and stay ahead of the competition

Today more than ever, it is necessary to differentiate oneself from the competition. You can achieve this goal by driving innovation. Choose our Laser texturing solution and you will be able to make your medical product innovative and unique.

Enter a new dimension

Today, you can create new textures on implant surfaces to give them specific properties and increase both part quality and patient safety. The execution of these textures is still most often outsourced and achieved by combining different surface treatment technologies such as coating.

3D Laser texturing is a fully digital technology that will not only surpass your present requirements but also open up a new dimension. With your imagination as the only limit, 3D Laser texturing gives you total freedom of design, flexibility and repeatability. As a result, you can drive innovation as you want, for the benefit of your clients.

Embed production data for traceability or add anti-counterfeiting features to make your device uniquely identifiable

Take your product design to the next level by executing your own textured designs in-house. And—with the same technology—protect your textured device from counterfeiting by applying uniquely identifying marks or series of numbers on each part you produce.

Optimize your manufacturing process and experience greater success with Laser texturing

GF Machining Solutions' Laser technology provides an innovative alternative for texturing, engraving and marking operations in a single setup. It can improve product quality, reduce risk, and reduce your production costs—all while simplifying your process.

Save time with one single setup

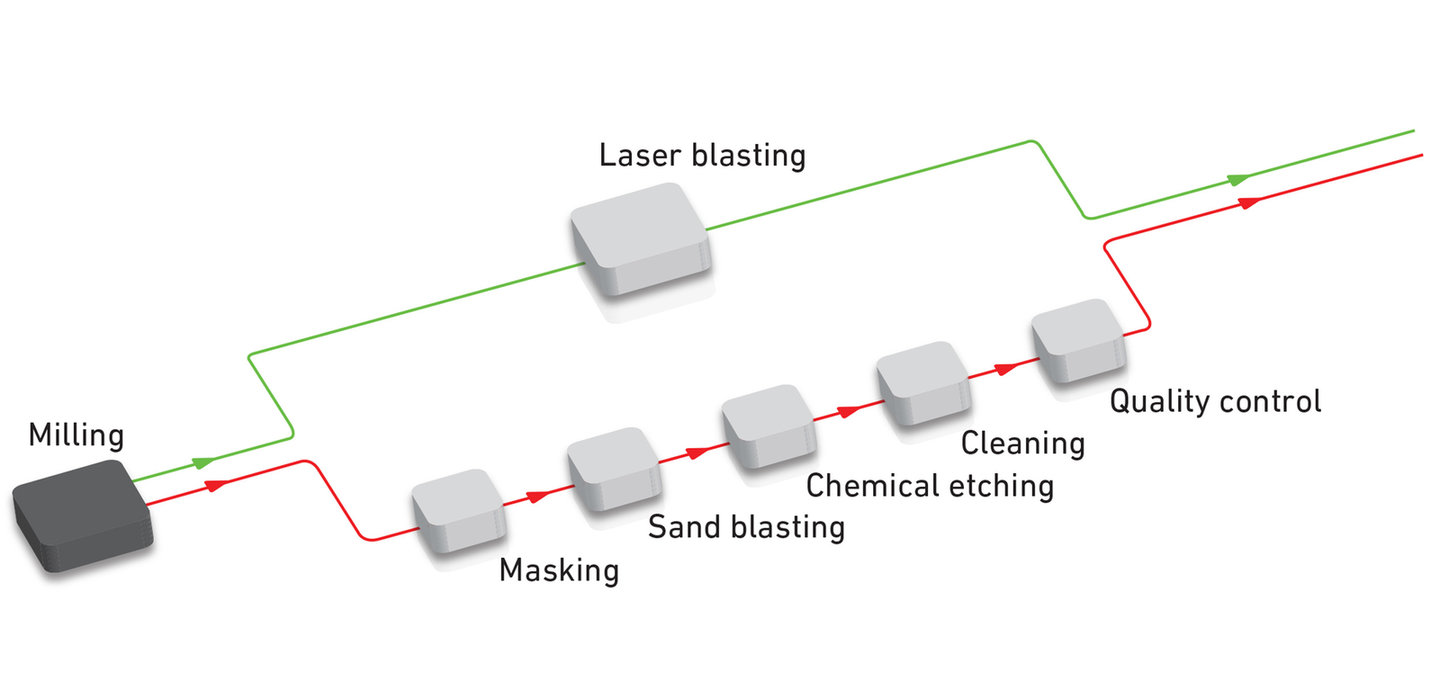

Our fully digital, zero-tool-wear Laser texturing solutions are a step forward and several steps less compared to traditional grit blasting and acid etching.

Our Laser texturing technology requires no cutting tools, electrodes or manual processes, such as masking, cleaning and inspection. You finish your operation in one single setup, even if you want to combine texturing and marking; you save time, align your process with lean manufacturing and are able provide faster lead times to your customers. Moreover, you can finally achieve the perfect repeatability that is crucial in your market.

With the nano- and femtosecond Laser solutions available in the LASER P 400, you have the perfect tool to outpace your competition by delivering the right quality with a stable, optimized manufacturing process.

Reduce contamination risks

Considering the by essence “non-contaminating” nature of light, research shows that the chemical composition of the surface can remain unaltered if laser ablation occurs in a neutral atmosphere (nitrogen or argon).

Laser technology also helps to reduce contamination risks by making manual operations obsolete and excluding the potential for chemical contamination from grit blasting and/or acid etching. You avoid the contamination risks―and costs―associated with part handling, secondary cleaning operations and the use of consumables (blasting material, acids, cleaning agents and other chemical products). As a result, you are able to avoid the use of traditional methods that are not only environmentally hazardous, but also limit your design potential.

Digital process for unlimited design flexibility, dedicated textures.

The surface of your device is enhanced by a fully digital process, so you achieve uncompromised part quality as well as perfect repeatability―without limitations in terms of design.

Unlimited design flexibility: Create products with many different textures, each targeted to perform a specific function

Research has shown that erratic textures improve osseointegration while geometrical textures tend to have antibacterial properties. With our Laser texturing solution, you can create many distinctive surface textures following any design you create— on complex 3D surfaces―and even implement different textures on a single device with unequaled precision.

The Laser texturing process starts with a digital bitmap/grayscale file created in-house—or from a natural surface by reverse engineering via 3D scanner. Our software eliminates the guesswork, so you achieve the exact results that your design requires.

Achieve perfect repeatability and texture continuity

With a digital process, it becomes easy to control texture continuity between two parts: Laser texturing ensures repeatable textures on every product made, with no deviation from your design in terms of quality.

Using a digital process that minimizes both operator intervention and secondary processes such as cleaning reduces risk and non-quality costs. Experience the game-changing advantage of a digital technology: stable quality throughout your production.

Laser texturing :

how it works

Since the 1980s it has been clearly proven that textured titanium surfaces ensure better osseointegration than smooth “as machined” surfaces. New technologies to create these textures offer a variety of options to device designers and manufacturers.

Grit/sand blasting

Manufacturers have used various techniques to produce functional surfaces; with acid etching alone or in combination with grit blasting as the dominant method. However, both are “dirty” processes, requiring masking of the part to protect areas that are not to be treated and leaving behind particulate and chemical residue that necessitate post-treatment cleaning operations. More recently, designers have adopted laser blasting due to its many advantages over older techniques.

Laser texturing: why and how

Laser texturing works because high-energy laser light interacts with metal’s surface, causing either ionization of small amounts of the surface, or both ionization and melting, depending on the laser type used. Laser blasting can create a surface with a repeatable structure allowing for osseointegration or vascularization, and can even impart antibacterial properties due to hydrophobic effects. Nanosecond lasers cause both melting and ionization of the material and therefore leave a heat-affected zone (HAZ), while Femtosecond laser directly ionizes the material, which results in a minimal HAZ and no burr at all. This highly efficient Femtosecond laser result is also called “cold ablation”.

Geometrical versus random

Using GF Machining Solutions’ Laser texturing technology, device designers can integrate various types of textures onto a single surface―and incorporate anti-counterfeiting features into the texture—with one single part setup. Our LASER P 400 U can be equipped with Lasers that work in pulse durations of nanoseconds, femtoseconds, or a combination of both, providing unbeatable flexibility. Designers can create surfaces that offer unmatched functionality—with digital repeatability and effortless quality.

PRODUCT : AgieCharmilles LASER P 400

www.gfms.com/com/en/Products/advanced-manufacturing/laser-ablation-texturing-family.html

Software is the key to quality

With GF Machining Solutions Laser texturing machines comes a complete suite of our own dedicated Laser texturing software that transfers your two-dimensional pattern onto a 3D surface with industry-leading accuracy, especially on curved surfaces. Unique Laser blasting capabilities are made possible on your five-axis surfaces thanks to the LaserDesignTM part of our suite of programs developed to ensure successful implementation of your Laser solution. Our application experts are happy to support you in bringing your ideas to life.

ARTICLE - Textured titanium implants

Laser texturing on dental implants: Limitless texture design possibilities