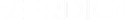

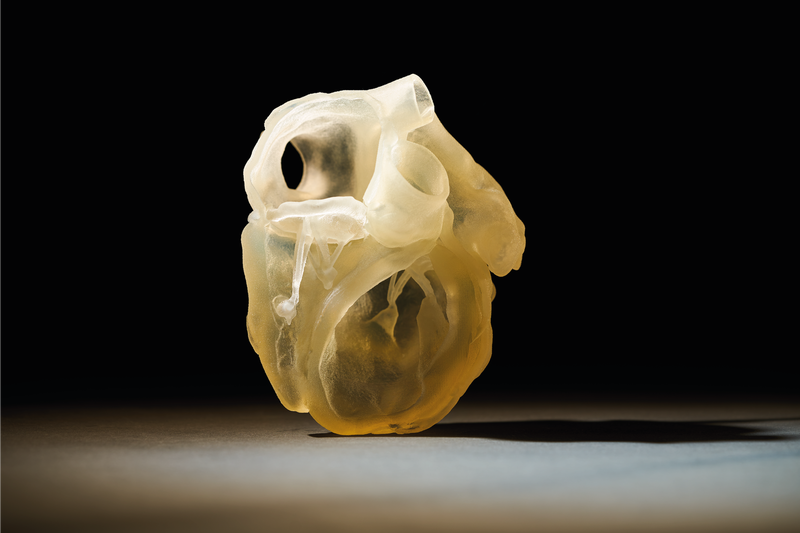

Images courtesy of Stratasys

This model of a human heart has been printed on Stratasys’ new J750 Digital Anatomy 3D Printer, which is available with three new materials that are designed to replicate cardiac tissue, vascular tissue and bone. The goal of the product is to provide a way to simulate clinical situations without the need for cadavers – making it a potentially vital tool for medical settings.

According to Stratasys Healthcare Business Unit Head Eyal Miller, the printer gives surgeons “a more realistic training environment in no-risk settings”, while helping medical device makers by “performing design verification, validation, usability studies and failure analysis with these new models”.

The 3D printer is already in use at a number of organisations, including the Jacobs Institute in New York, the US, where it is being used to recreate vascular components for testing and training. According to chief medical officer Dr Adnan Siddiqui, it provides the long-desired “live-tissue feel and biomechanical realism”, allowing the organisation to “simulate actual clinical situations and to study new devices to establish their effectiveness before introducing them to patients”.