COMPANY

INSIGHT

Our markets include Medical Device, Aerospace, Oil & Gas, Semiconductor and many other Industrial and Scientific Research institutions. SMD is a privately held company serving the United States from its Wallingford, CT headquarters and Europe from its location in Chedburgh England.

SMD offers an integrated engineering design process with our customers, often providing a design to fit within very tight envelopes and under harsh operating conditions.

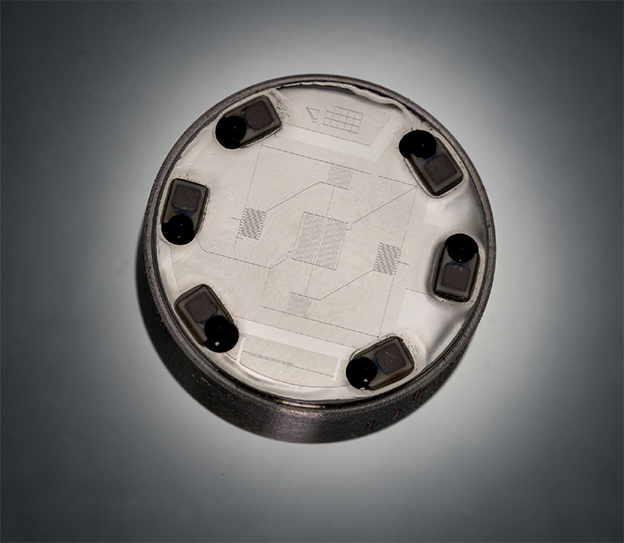

Unique among strain gage load cell manufacturing, SMD uses a sputtered thin film process to create the electronic strain gage circuit. This process involves the sputter deposition of thin films of dielectric and resistor alloy onto metal components. This process forms a molecular bond with the component with no adhesives involved thereby eliminating the adhesive-based errors associated with other bonded strain gage load cells. Further, our strain gauges are accurately positioned and balanced using state of the art laser trimming technology. This process provides us the ability to place the strain gage circuit on extremely small surface areas (1mm^2) which in turn provides endless capabilities to reduce design footprints from our customer’s application.

Image - Sensor 1

For fluid management systems including Medical IV and Syringe Pumps, RF Oblation Systems, Enteral Feeding Pumps, Urology Diagnosis Machines, Clinical Chemistry and Immuno Assay Diagnostic Machines, SMD offers highly repeatable and accurate bubble sensors and occlusion sensors for tubing as well as flow meters. The bubble sensors use state of the art ultrasonic technology to non-invasively detect bubbles as small as 1 microliter using dry coupling and advanced signal conditioning. Occlusion sensors are also non-invasive in nature and use our thin film load sensors to detect a rise in pressure created when tubing is blocked or to verify if certain valves or valve manifolds are positioned correctly. If flow rate is desired, our non-invasive clamp-on design or our low flow in-line design provides accurate flow rate data as well as totalized flow volume, signal strength, and average speed of sound of the fluid through the device. Speed of sound can be used to detect or differentiate certain types of fluid. The FlowDAQ control and display flow module can be calibrated to offer 1-2% accuracy for a given temperature and fluid type. Finally, custom weight scales can be used to measure liquid volume in bags and other container types. This data can be used as feedback to control the device’s flow rate and fluid management.

Other unique products include:

• A new standard line of hanging scales capable of accurately measuring ranges from 0.4 to 110 pounds (0.4 to 50 Kg). Excellent choices for single use bag systems.

• A non-invasive small diameter tubing pressure sensor. This unique device is made up of a two part assembly that easily snaps together. One part is reusable (the pressure sensor) and the other part is a low cost disposable flow module. Tubing diameters up to ¼”.

• A simple to use USB converter box used to connect our sensors to your computer for data streaming.

• Ultrasonic Liquid level sensors made from stainless steel or polypropylene providing a non-mechanical highly reliable level switch. Available in cryogenic models.

• A low profile (less than 1” high) stainless steel weight scale with 4-20mA output used for gas cylinder weight monitoring in semiconductor critical gas distribution systems.

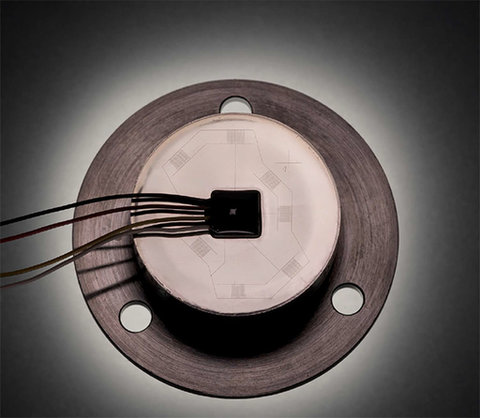

Image - Sensor 2

Please refer to our upgraded website for more information at www.smdsensors.com