Company Insight

Sponsored by Alleima

Nitinol’s super elastic solution to medical implants and instruments

The medical device industry is a changing landscape, with ongoing developments in digitalisation and innovations leading to minimally invasive devices. With its shape memory and super elasticity properties, how will nitinol play a part in the future of medical technology?

Metallurgy can be a complicated balancing act in the medical technology field, with device manufacturers needing to find the right combination of properties for their application, in addition to requiring biocompatibility.

From stainless steel to copper-based alloys and gold plating, the list of metal materials used in medical devices is an extensive one, so what makes nitinol so special? Offering unique properties such as shape memory, super elasticity, biocompatibility and fatigue resistance, nitinol has consistently been the answer where cheaper options (such as stainless steel), have failed.

Biocompatibility for instruments and long-time implants

Nitinol is a combination of approximately 50% nickel and 50% titanium, although this differs and each alloy is named according to the weight percentage of nickel. Despite nickel being toxic, nitinol is highly biocompatible due to the titanium oxide layer.

“Biocompatibility is extremely important for implants, but also instruments,” says Dr. Bernd Vogel, Global Technology and Innovation Manager at Alleima’s medical unit and a renowned expert in the field of nitinol processing. “If you do the right surface finishing, you will increase that further, so it’s no problem to have nitinol as a long-term implant.”

Alleima designs and develops nitinol components, as well as complete finished products at its production unit in Karlsruhe, located in the south of Germany.

Shape memory

Nitinol’s shape memory allows it to undergo deformation at one temperature, stay in its deformed shape, and recover its original shape after being heated above its transformation temperature.

According to Dr. Vogel: “Nitinol can be used for medical instruments that have to be shaped to the anatomy of the patient. Normally, when you have a stainless-steel instrument, you need to have maybe ten different angled instruments, but with nitinol you only need one instrument bent to the angle needed for the operation. Afterwards, during the sterilisation process, it goes back to the straight instrument ready for the next surgery.”

Super elasticity

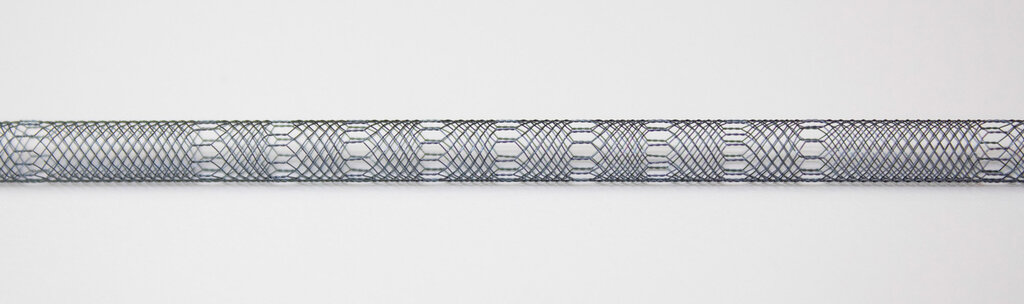

Above its transformation temperature, nitinol will behave super-elastically. This means that it can undergo significant deformations and immediately return to its original shape once the external load is removed.

“The super elastic properties don’t need heat. You constrain, you crimp, you pull through a tube. Then you push it into the body,” Dr. Vogel explains. “The system of tubes in the body is very complicated and very long, and we don’t want to cut open the body until we get to the point of interest. We want to go endoscopically. That’s why endoscopic instruments are getting small in diameter, longer, more flexible, and softer.”

Crimping is an effective joining technique for nitinol wire, meaning it can be connected to other nitinol components or different materials (such as stainless steel).

Braiding and Twisting detail center. Credit: Alleima

“The next generation will work with soft endoscopic robotics, which go deeper in the body, and there you have to use flexible instruments,” Dr. Vogel adds. “This is our field, we can crimp our devices and apply them to these robotics and then they open in the point of need. This is where you need super elastic properties – stainless steel can’t do that since it is too rigid, and the elastic properties are far too low in order to fulfil these needs."

“It’s the same with implants. You want to apply them through a very small catheter, a very small diameter application system. Then they should open up 20, 30 times bigger when you apply it, therefore, you need extremely high super elastic properties, as well as a stable and stiff implant. These are exactly the properties nitinol offers.”

For more information about nitinol, its processing, and medical applications, visit Alleima´s webpage: www.alleima.com/nitinol.

Contact information

Alleima Advanced Materials

1 Commerce Blvd.,

Palm Coast, FL, 32164,

United States

Tel: +1 386 445-2000

Fax: +1 386 447-5113

Email: sales.pc@alleima.com

Alleima Tucson

2424 East Aragon Rd

Tucson, AZ 85756

United States

Tel: +1 520 495 5927

Alleima Karlsruhe

Wilhelm-Schickard Str. 9c

761 31 Karlsruhe

Germany

Tel: +41 41 761 63 55

Email:sales.ka@alleima.com

Alleima St Imier

Rue de Beau Site 8

CH-2610 Saint-Imier

Switzerland

Tel: +41 32 942 39 20

Email: sales.sb@alleima.com