COMPANY

INSIGHT

Biocompatible Coatings for the Evolving Medical Device

BioInteractions has dedicated over twenty-five years into researching and developing innovative, biocompatible materials for medical devices. Throughout this time, we have maintained our position at the forefront of research and development of sophisticated biocompatible coatings.

Our commitment to advance healthcare through innovation, has resulted in a range of proprietary coatings which targets the core issues faced by medical devices. Our years spent tackling a wide range of challenges gives us a unique advantage when providing an optimal solution for our partners. Our coatings are proven to improve the biocompatible response of a surface over long periods of time.

The following are a few of the key medical applications where ElectroCraft motors empower medical motion control.

Commitment to Care Services:

Our expertise and broad product range has given us in-depth experience in tackling a wider range of challenges compared with other coating providers. This helps us to realise the importance of the application of the coating in order to achieve optimal efficacy on the surface. We have found that a quality application process improves the effect of the coating and allows the coating to be utilised on a wide variety of surfaces. Our know-how in these areas allows us to provide a high-performance coating and a tailored coating process to fit our partners’ requirements.

Additionally, we have spent a significant amount of time and effort developing test methods which help to highlight the benefits of our coatings on the device surface. This added value helps to add supportive data to regulatory submissions. We have assisted our partners with their regulatory efforts and have expertise with this process. Our support in this area combined with our ability to provide a tailored solution is a comprehensive service to help our partners with their challenges.

Our Commitment to Care service (C2C), and our high-performance coatings is the complete solution for our partners who require a coating. We provide world-leading coating technology optimised for specific applications, in combination with our C2C service to help our partners navigate through their product development, resulting in market leading medical devices.

We have created a range of non-leaching, biocompatible coatings which utilise the benefits of a multi-faceted approach in tackling biocompatible challenges. Our high-performance coatings provide significant benefits to the material as well as to the patient. This is achieved by using a combination of active components with passive components to give unique advantages offered by our technology.

BioInteractions manufactures and supplies these coatings, as well as the services to coat devices. We have combined our technology with our C2C services to provide the optimal solution for our partners.

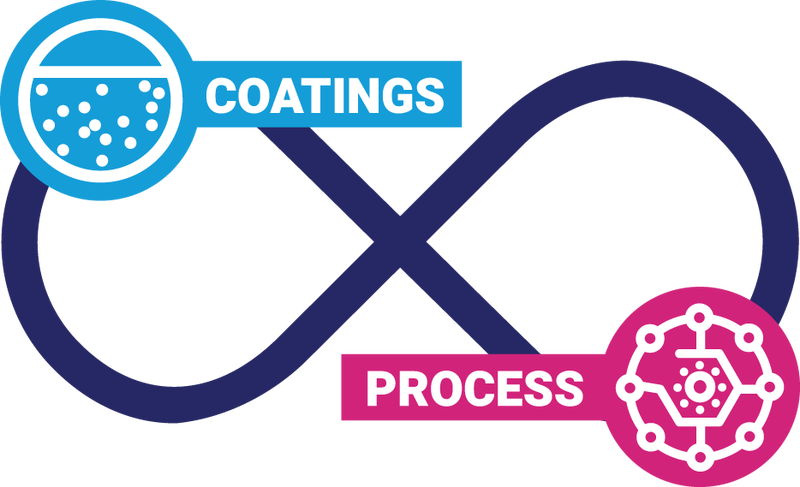

Astute®

Triple-Endothelial Action

Anti-thrombogenic Coating

Why Astute®? (Benefits)

The Astute® Antithrombogenic Coating is a non-leaching coating that actively improves the haemocompatibility of a device surface by mimicking the natural endothelial layer. Our coating enables a device to perform its intended function as well as reduce the risk of further complications from occurring in the patient.

The coating provides a unique way to prevent thrombus formation as well as cellular deposition and adhesion onto the device surface. This hinders thrombus formation at the site and reduces the risk of them forming further along in the patient. There are no leaching components which further reduces the patient risk and helps the coating to perform well over long periods of time without reduction in performance.

What is Astute®? (Features)

Astute® Antithrombogenic coating uses an active antithrombogenic component combined with additional passive components to mimic the natural endothelial layer. The active component causes the coating to interrupt the blood cascade mechanism.

This prevents platelets from activating and hinders thrombus formation. Astute® uses additional passive components to reduce deposition and adhesion on the device surface. This combination actively prevents thrombus formation, is non-leaching and reduces deposition onto the surface. This multi-faceted approach provides superior haemocompatibility to the surface and delivers significant benefits which leads to an improvement in the patient’s well-being.

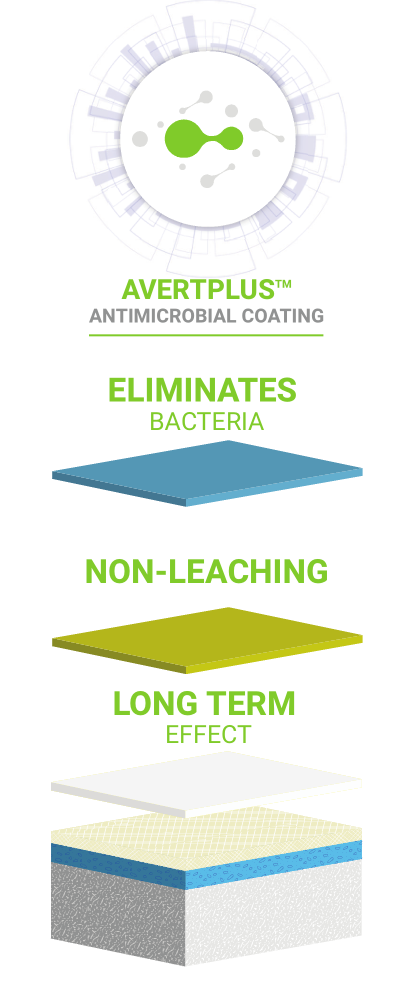

AvertPlus™

Dual Active Contact Kill Mechanism

Antimicrobial Coating

Why AvertPlus™?

AvertPlus™ Antimicrobial is a non-leaching coating that eliminates bacteria on a surface and helps to reduce biofilm formation. The coating targets a broad spectrum of bacteria, without harming the patient’s cells. This significantly reduces the risk of infections and the risk of coating components to the patient.

The non-leaching coating provides a consistent effect without any degradation and helps it to survive long-term applications. Additional, passive components enhance the effect of the coating by reducing deposition and adhesion of cells onto the surface. The coating provides these benefits without the use of toxic compounds, eluting components or antibiotics. This reduces toxicity risk or risk of antibiotic resistance to the patient. The two-factor approach prevents infections from arising as well as from spreading, which significantly reduced the risk to the patient.

What is AvertPlus™?

AvertPlus™ Antimicrobial Coating uses an active agent combined with a passive component to eliminate the infection and prevent bacterial colonisation on a surface. This dual functionality gives the coating advantages over alternatives for tackling device related infections. The contact kill mechanism causes the cells to physically lyse and hinders biofilm formation.

This significantly reduces the ability of bacteria to remain on the surface and colonise. The combined active and passive components of the coating provide an effective method to eliminate bacteria, prevent biofilm formation and inhibit a broad spectrum of bacteria from colonising on the surface.

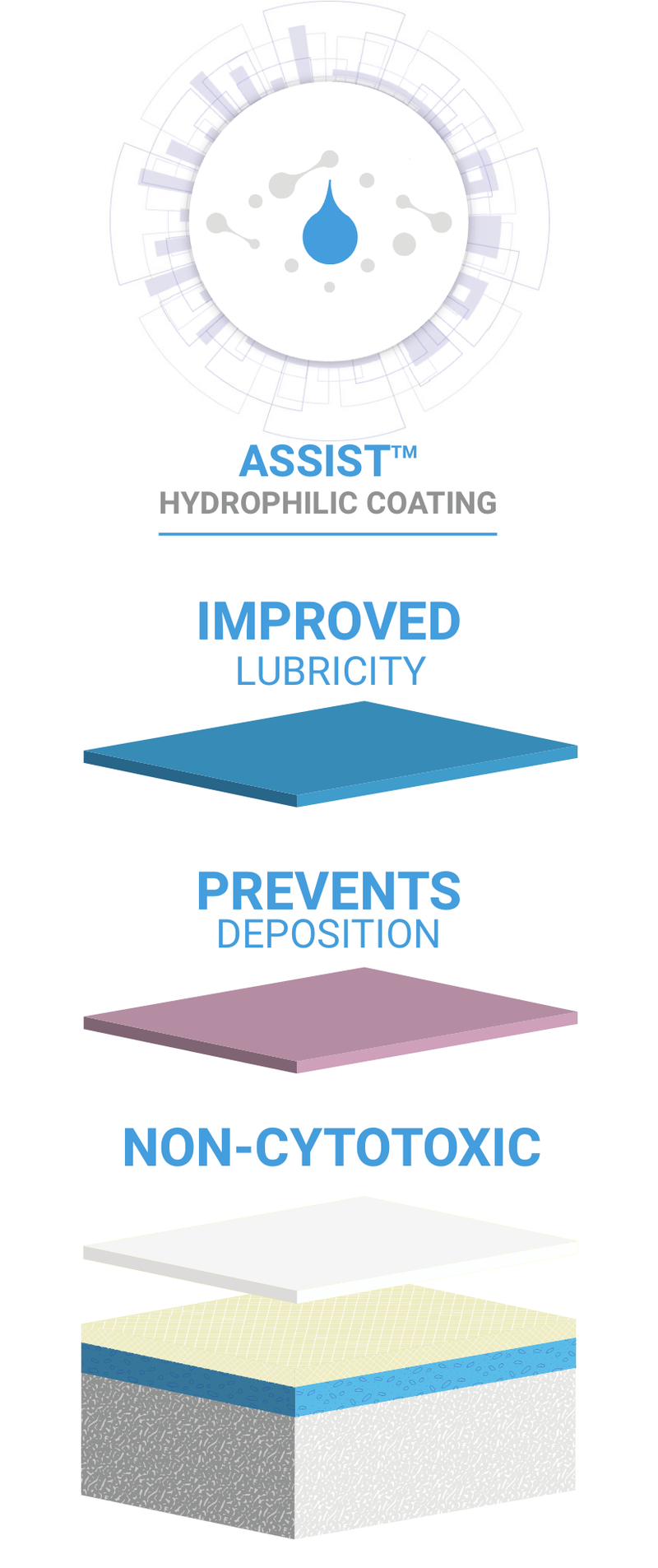

Assist™

Enhanced Lubricious Activity

Hydrophilic Coating

Why Assist™?

The Assist™ Hydrophilic Coating delivers a high-performance, hydrophilic surface for long term applications. The coating significantly decreases frictional resistance between the tissue and device interface. This reduces tissue damage and improves comfort when delivering or removing a device in a patient. Assist™ uses a two-factor approach to innovatively improve stability, which helps it to perform for long periods of time.

This allows the device to remain in its environment for longer applications and has the stability to withstand challenging conditions. The stability of our coating helps to reduce the amount of times a device is required to be changed and improves the patient’s comfort.

What is Assist™?

Assist™ Hydrophilic Coating uses a two-factor approach to reduce the friction at the device-body interface and maintains its function for long periods of time. The coating includes a non-thrombogenic agent which prevents deposition and adhesion of cells onto the device surface. This helps the long-term performance by reducing ability of components interacting with the surface.

The coating hinders occlusion of the device and allows the device to remain in position for extensive use which helps improve the patient’s comfort. Assist™ utilises a two-factor approach to reduce the complications at the device-body interface. The friction is reduced between the surfaces to improve the delivery and removal of a device and minimises tissue damage which helps improve the patient’s comfort and well-being.