COMPANY

INSIGHT

EXERA™ - Sandvik’s brand for unique life changing medical solutions

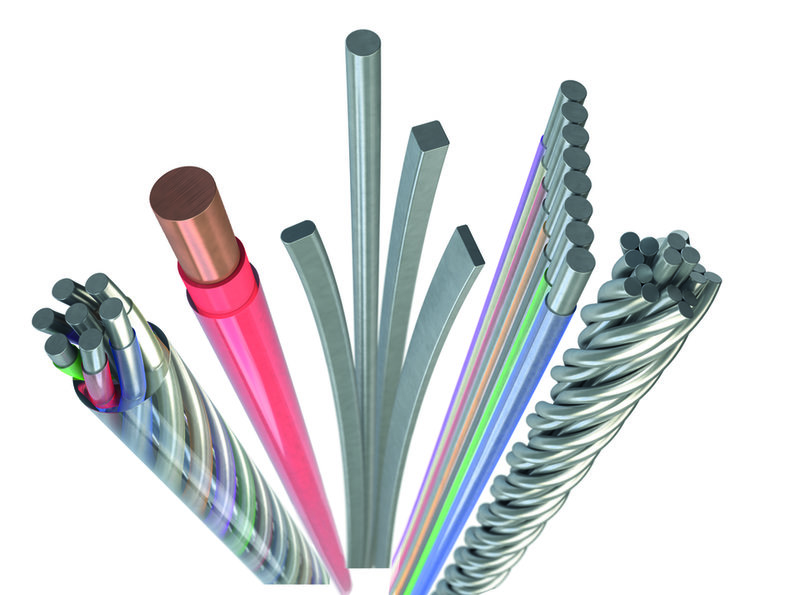

Precision medical wire is an essential component of many medical devices. Sandvik's EXERA™ program of alloys, wire forms and wire components, wire diameter range and coating types can be combined to match unique applications. We can also do all sorts of different process operations - we offer a "one-stop shop" solution. Together we can design a process and product that cannot be found anywhere else in the world.

EIGHT GOOD REASONS TO CHOOSE SANDVIK

- AN INNOVATIVE PARTNER

It pays to choose a supplier with innovative thinking to be your joint research and development partner who also can play a vital role in your team.

- MATERIAL SCIENCE EXPERTISE

Let your projects benefit from our unmatched expertise in metallurgy and fine medical wire production. We have extensive research and development and materials capabilities and offer a comprehensive product portfolio under the brand name EXERA™.

- VALUE ADDED CAPABILITIES

We can also give you added value in the form of cut-to-length orders, twisted leads, micro cables, thermocouple sensors, coils, clean room class 7 manufacturing, and more.

- LEAN STATE OF MIND

We are leading the way in process improvement and continually strive to increase quality, while decreasing waste and variability.

- A RESPONSIVE SUPPLIER

Your business deserves a flexible partner who will adjust to your design and production schedules and provide excellent customer service with short lead times.

- STRICT QUALITY ASSURANCE

There are major quality benefits for your business if, like us, your supplier has control of the entire value chain, from melt shop to end-product.

- WITH US, SIZE DOES NOT MATTER

Whatever the size of your order or organization, large or small, we want to work closely with you, from the development stage through to mass production.

- FINANCIALLY STRONG

You can benefit from a financially strong single-source partner for fine medical wire and wire-based medical components who can help you achieve long-term sustainable growth.

Over 150 years of experience at your service.

For more information: https://exera.sandvik

Sandvik's EXERA™ program of alloys, wire forms and wire components, wire diameter range and coating types can be combined to match unique applications

Sandvik’s Tetrode wire is very popular among universities and is commonly used for nerve stimulation research and making electrodes.

A key competence at the Sandvik Palm Coast facility is coating where we besides traditional polymer and PTFE coatings also can offer custom formulations.

We can also provide different type of spool types and sizes.

Materials and components we offer:

Materials we offer: Stainless steel grades, MP35N, copper based alloys, , additional medical and precious metal grade alloys such as Pt, PtIr and Au and multiple resistance alloys.

Product forms including wire, fine wire, coated wire, flat wire, plated wire, coils, guidewire material, multi-filar wire forms as micro cables or stranded constructions.

The alloy or base material can be supplied with or without a polymer coating in various colors. Typical thickness is 2,5 µm – 25 µm (.0001” - .001”), thicker on request. Surface finishes can be modified with gold, nicker or silver plating or provided with an oxidized layer (when not a noble metal).

Straightening of the wire is one of our core competencies.

Our in-house die craftsmen and women utilize a combined experience of over 100 years to put the precise art of die making at your service.

Sandvik’s EXERA™ brand incorporates ultra-high-quality wires are a result of quality diamond dies.