COMPANY

INSIGHT

EQUFLOW SENSORS: SINGLE USE AND DISPOSABLE FLOW SENSORS FOR MEDICAL EQUIPMENT

In medical technology- and production processes, it's all about utmost reliability, accuracy, and safety. False measurements are unacceptable when using a dialysis system, for instance.

Equflow develops and produces modular flow sensors based on a unique and extremely reliable principle. The sensors are so-called turbine flowmeters furnished with an infrared sensor enabling flow measurement of a big variety of liquids.

The use of these disposable flow sensors reduces down-times during your production process and hence saves energy. A lengthy and intensive development and validation process preceded the commercial introduction. The result is an extremely accurate measurement system that guarantees a reliable flow measurement. An automated calibration system is applied to offer maximum accuracies every time wettable parts are exchanged.

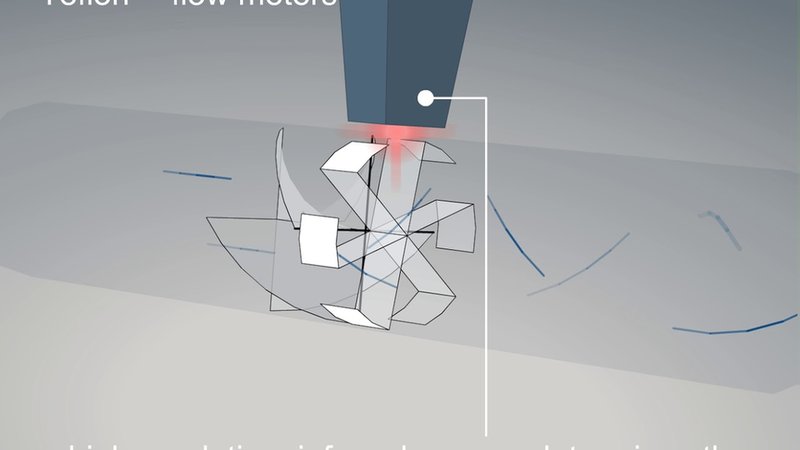

Turbine Flowmeter

A flowmeter measures the quantity of liquid that flows through a tube per unit of time: the flow rate. Depending on the application, the instrument measures the mass, volume and/or flow rate of the product.

Equflow uses the turbine flowmeter for flow measurement which has two significant advantages: the accuracy and repeatability when measuring the flow of low-viscous liquids. Equflow has developed a mechanical construction that results in an almost frictionless turbine movement that barely causes any wear and tear.

The infrared sensor in a turbine flowmeter measures the number of pulses that the reflectors on the six turbine blades generate. The more pulses the IR sensor detects, the faster the medium flows. A PLC or other controller then converts the square wave pulse signal into flow and/or volume. In a disposable application, it is important that the sensor is placed separately from the turbine shaft, so that the IR sensor doesn’t get in touch with the fluid measured.

Single Use in Medical Technologies

In medical technology, there are strict requirements for flow measurement. The measurements must be reliable, accurate and performed in sterile conditions. Therefore Equflow’s’ single-use flowmeters are produced in a clean room and can be sterilized by gamma radiation if required. A dialysis system, for example, must be able to be cleaned quickly and easily after each run.

This applies to all sorts of medical devices and equipment that process (body) liquids. Avoiding contamination and/or infection is of the essence. Moreover, shorter process- and cleaning times ensure lower costs for production and save energy.

How Does it Work?

Basically, the modular sensor system consists of four components; the flow tube with turbine and the bar code scanner are the most advanced parts. These guarantee the accuracy and reliability of each flow measurement for years.

The components:

- Turbine tube for single use;

- Bar code scanner system for automatic calibration;

- Choice of housing for the disposable tube;

- Electronics for flow measurement.

Turbine Tube for Single Use

A turbine tube for single use is placed as a connector between two hoses that transport the liquid from or to a component of the machine or device. The flow tube holds the mini-turbine, which turbine blades are detected by the IR sensor beaming through the transparent tube wall. The turbine is very light (negligible mass) , so that even minor flow variations can easily be detected. Equflow uses PFA or PVDF as transparent disposable materials of construction. Turbine tubes are available in different sizes that cover flow ranges from 20 mL/min up to 200 L/min.

Bar Code Scanner System for Automatic Calibration

Each turbine tube is supplied with a unique bar code, comprising of the K factor (amount of pulses/Liter) of the tube, amongst other data such as lot number, serial number, etc. The respective K factors are determined for each tube by using a calibrated testing procedure.

The fluid properties and other specifications are set in the process system of the production or control process. When the turbine tube is replaced, the operator only needs to scan the new bar code with the bar code scanner. The new K-factor will automatically be uploaded in the computer and consequently a reliable measurement will be guaranteed again.

Choice of Housing for the Disposable Tube

The working principle of Equflow’s flow sensors is based on the count of the reflections of the six turbine blades. Different housings are available to hold the disposable tubes. The most suitable model for a process depends on the system and how often the flow tube has to be exchanged.

Electronics for Flow Measurement

Converting the digital turbine pulses produced by the infrared sensor into volume or flow can be done by a controller. Equflow offers single and dual flow controllers as well as batch controllers. Contact Equflow to learn more about the possibilities.