COMPANY

INSIGHT

Industrial Indexing Systems, Inc is now in its fourth decade in the motion control business

We are dedicated to providing quality products and services that enhance our customer’s success.

We provide complete motion control system solutions as well as individual components for the industrial motion control market.

From engineering the hardware and software for applications, through to commissioning, training, and field service, we deliver expert, professional guidance and support. As you read this, thousands of axes of IIS motion control products are operating all over the world, providing dependable, high performance motion control.

At IIS we strive for continuous quality improvement and innovation. In 1978 we were one of the first companies in the world to develop and manufacture microprocessor-based digital motion control systems for industrial and commercial use. That pioneering spirit, tempered with years of experience, continues today as we regularly introduce new products into the market.

To accommodate the steady growth, we’ve enjoyed over the years, our facility has been expanded several times to its present 17,000 square foot capacity. This location houses all critical departments - Sales, Marketing, Applications Engineering, R&D, Production, Warehouse, Panel Shop, Quality Control and Customer Support. Having everything under one roof speeds communications and provides better service to our customers.

The typical IIS customer is an Original Equipment Manufacturer producing machines for resale into some specific market. We are often involved at the very beginning of the design for a given machine. It is not unusual to find one or more of our engineers at a customer’s plant working with the OEM’s engineers to create a machine that will become a market leader. We are, in every important way, a full partner with the OEM in the design, manufacture, sale and support of his equipment.

Our business philosophy is quite simple. We take responsibility for the entire motion control system. To do that we make a long-term commitment to our customers for the entire system: system level applications assistance, system level specifications, system level hardware and software, system level documentation and support. And our Guaranteed System Performance pledge gives our customers the security of knowing that their system will work as specified or we will make it right.

We offer a wide variety of products to meet most OEM applications. From smart drives and motors to single and 1- ½ axis integrated positioners to open architecture SERCOS based multi-axis systems all with user friendly software tools to make application programming quick and easy. All systems are available with a range of motors from 30W to 22 kW, with integrated resolver and encoder feedback devices.

Our objective is to bring state-of-the-art servo system products to practical use that make economic sense. Whether it is a complete turnkey system or servo components, IIS’ commitment to quality products and personalized support is unsurpassed. Our business philosophy is pretty simple. We take responsibility for everything we sell. By doing that we make a long-term commitment to our customer’s success.

The IIS Quality Mission

Industrial Indexing Systems is committed to providing quality motion control products and services to our customers, thereby building long term relationships. Total Quality is the cornerstone of IIS’ commitment to our customers and suppliers. IIS pledges to provide the necessary resources in terms of people, training, equipment and procedures to meet this Total Quality Commitment.

Luminary Series fits the medical automation market

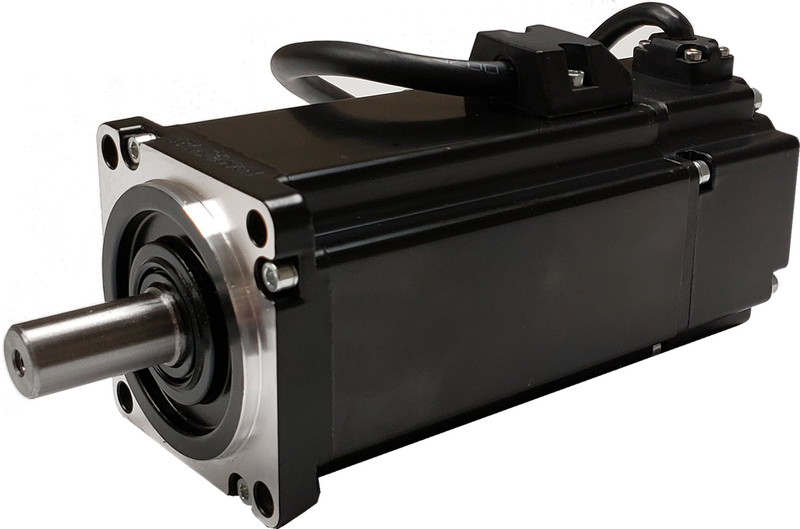

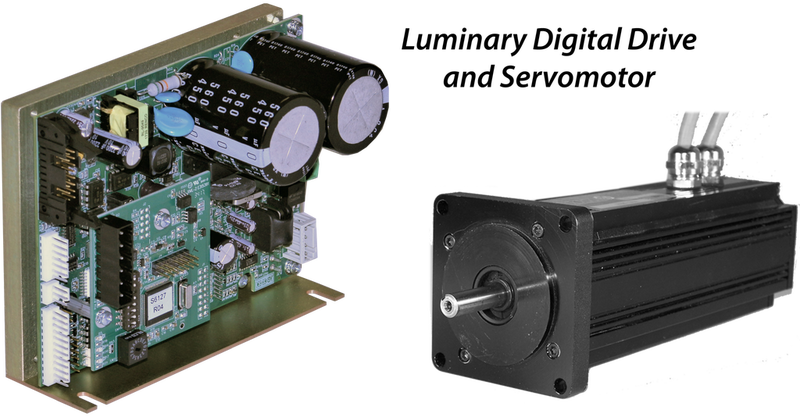

High volume custom configurations engineered for the exact function and fit is why the Luminary Series is part of the Industrial Indexing Systems’ product offering to the automation medical market place. Luminary Series products include the single axis motor and drive and multi-axis motor and drive systems functioning in simple torque, velocity or position control mode.

A product’s form, fit, and function are important to an original equipment manufacturer (OEM). All the Luminary system components are configurable in size and shape to meet your requirements. Dedicated design engineers are ready to discuss how our system can be best utilized for your project.

We select the most efficient motors for the job, write software to perform the required motion sequences, I/O functions and communications; all packaged into a system with the form and function you need. OEM package designs can range from a kit of parts to a custom enclosed turnkey system you can plug in and turn on.

Flexible built-in I/O for digital and analog sensor interfaces not only keep the size of the system down but also the cost.

Inexpensive software tools are available for the system sizing, system functions, and commissioning. Operator interface development is offered using standard off-the-self displays, custom designs or external PC based HMI display units.

Industrial Indexing Systems guarantees servo motion control systems to meet your specification needs.