How breath analysis simplifies early detection of diseases

Despite cutting-edge medicine, many diseases are often detected too late, causing much suffering to the patients and enormous healthcare costs through therapies. The earlier diseases can be detected, the fewer therapies or invasive treatments are needed, which leads to considerable healthcare savings.

Up to now, the early detection of diseases has been limited to preventive examinations such as blood counts or gastrointestinal endoscopies. In most cases, however, such examinations are only carried out when the patient already notices changes in his or her state of health. Additionally, these preventive examinations can be either quite expensive and time-consuming or very often also unpleasant or painful for the patient.

Breath gas analysis, on the other hand, is a proven solution to many of these medical challenges. Through blood circulation, almost all metabolic products from our blood are also found in our breath, however, in much lower concentration. With optical gas detection modules, like the new LGD Compact from Axetris, the analysis of exhaled air can be done quick and easy and without unpleasant side effects for the patient.

Which technology best serves the needs?

One of the most important technologies for the detection of metabolites in breath so far is gas chromatography in combination with mass spectrometry (GC-MS, and different variations or further developments of it). This method is very well suited to detect larger volatile organic compounds (VOCs) or to map the entire molecular fingerprint of a breath sample with a broad spectrum. For this reason, the GC-MS technique is very popular in research and pre-clinical testing. However, for precise quantification of single molecules or for the detection of small molecules, this technique reaches its limits. In addition, GC-MS devices are often very expensive and require highly technically qualified personnel for its operation and especially the evaluation of the results. Therefore, this technique is not suitable for being available to a broader public in clinical diagnostics in hospitals or medical practices.

In home care devices for example, gas sensors based on electrochemical or semiconductor technology are very popular. These are so small and compact that they can easily be carried in a handbag. This is a great benefit, especially for patients suffering from food intolerance, because they can use the device right before and after their meals regardless of location. However, since these sensors are based on the principle of a chemical or physical reaction between the target gas and the reactive sensor surface, that makes them age very quickly or change their characteristics over time, which is why these devices must be recalibrated or even replaced regularly. Furthermore, a reaction with other gases cannot be excluded, which can lead to cross-sensitivity of the target gas to be measured, and moisture in the breathing gas often leads to malfunctions that no sensor diagnosis can detect.

Besides technologies for research and home care, newer technologies, such as optical gas detection, have proven themselves in clinical practice.

Non-dispersive Infrared Sensors (NDIR) is a technology worth discussing as it is found in many areas of medical diagnostics, such as capnography or the Helicobacter Pylori test. This technique uses broadband infrared sources that image a very large portion of the infrared spectrum. The gas of interest in the middle of this spectrum is then targeted using appropriate band pass filters. However, since the ability to narrow down these filters is limited, cross-sensitivity to other gases is a recurring limitation. In order to design NDIR sensor solutions more selectively, spectrally several gases must be measured and mutually compensated, which is causing relatively high calibration costs. This ultimately leads to significantly higher complexity plus costs and susceptibility to sensor property changes over a longer period.

Axetris Laser Gas Detection modules are based on TDLAS (Tunable Diode Laser Absorption Spectroscopy) and focuses on spectroscopy of gas molecules in the infrared spectral range. The main advantage of TDLAS is the specified wavelength of the laser, which can be used to focus precisely on the target gas without interference from other gases.

How TDLAS Technology in the LGD Compact works in practice

Infrared (IR) spectroscopy makes use of the binding vibrational and rotational states of gas molecules. These vibrations and rotations are excited by the absorption of photons. As a result, many organic and inorganic compounds exhibit absorption bands in the near and mid IR. The strongest absorption bands are usually in the mid IR. In the near IR are the so-called overtones, these are often strongly attenuated absorption bands of those in the mid IR.

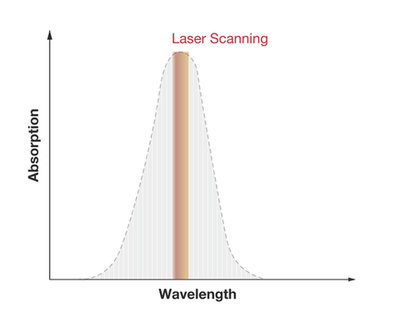

Gas absorption band as seen in low resolution (e.g. NDIR). High-resolution observation reveals a fine structure of individual vibration and rotation bands.

TDLAS scans individual vibration or rotation bands of the molecules in a high-resolution measurement.

With TDLAS, narrowband semiconductor lasers are used whose wavelength is tuned to the absorption line of the target gas. After absorption of some photons from the target gas, the remaining light from the laser hits a photodiode. The absorption is calculated according to the Beer-Lambert law. Here, the amount of absorption depends on the path length of the laser light in the gas cell and the absorption coefficient of the target gas. Electronic lock-in technology allows separating the gas absorption information from electro-optical system information, leading to a detection method eliminating the need for a physical reference channel and offering continuous sensor status monitoring.

To increase the detection limit in this process, it is common to extend the path of the laser beam. For this purpose, it is state of the art to use so-called multi pass cells, such as the Herriott Cell. In such a gas cell, the laser beam is multiply reflected between two mirrors before it hits the photodiode. With currently available solutions, path lengths of up to several meter for flow through gas cells designs or even kilometer for open path approaches can be achieved.

Is TDLAS the key technology for breath analysis?

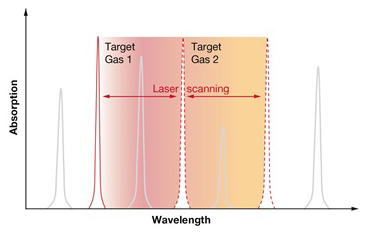

As can be seen for the LGD Compact a TDLAS module can typically be built quite small and robust, making it perfect for integration into small enclosures such as those used in medical practices or hospitals. The simple design of the LGD Compact also eliminates the need for time-consuming preparation of breath samples, as the patient can deliver them directly to the device. With optical measuring instruments, only filters for particles and moisture are recommended to prevent contamination and condensation on the optical surfaces. In addition, experienced specialists are not needed neither for the application nor the evaluation, since a TDLAS is ideal for the detection of one to three gases due to its limited wavelength.

The response time for TDLAS depends mainly on the gas flow and the volume of the measuring cell. The LGD Compact was designed with a very small gas cell that has a volume of 19 ml. This will allow continuous real-time monitoring for even the smallest gas flows of less than 500 ml/min. Continuous real-time measurements also enable the monitoring of metabolic processes during therapies.

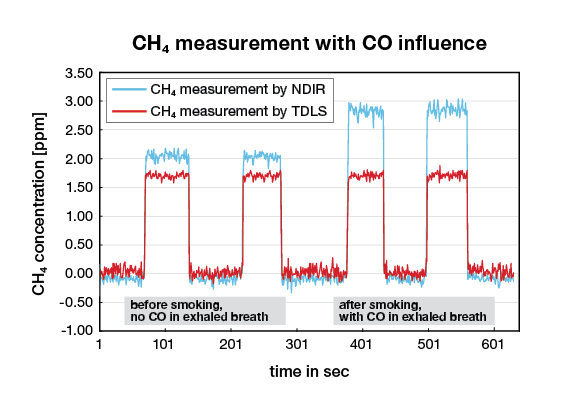

Due to the wavelength of the laser being exactly matched to the target gas, cross-sensitivities to other gases can be avoided or compensated by an additional measurement. A good example of this is CO in the breath of smokers. In measurement methods such as NDIR, the CO peaks close to CH4 causes cross interference and thus falsifies the results (see also the following diagram). With the LGD Compact using TDLAS technology, the methane measurement is free from CO influences and other disturbing components.

Measurement of exhaled breath from a smoking person before and after smoking a cigarette. Between the breath peaks the devices were purged with Nitrogen.

Since TDLAS technology is very robust and ensures stable and consistent high-quality measurement results over many years without the need for recalibration, uniquely low operating costs are achieved. In addition, all Axetris Laser Gas Detection modules feature continuous status monitoring to inform the user in a timely manner of any problems that may arise. This eliminates the need for preventive maintenance.

In summary, TDLAS technology in the LGD Compact is a perfect solution for the detection of smaller molecules and is thus a useful complement to GC-MS technologies. The trend in TDLAS is clearly towards the mid IR spectrum, where gas molecules with detection limits in the sub ppb range can be achieved. Axetris is pursuing the strategic goal of implementing dedicated TDLAS solutions in the mid IR for breath gas analysis in the future.

The use of TDLAS in Gastrointestinal Diseases

Axetris LGD modules have been successfully used for years for the detection of gastrointestinal diseases, which include lactose intolerance and bacterial overgrowth. Complex sugars, for example, are not split up by the body but processed as in a fermenter. Among other things, this produces hydrogen, which is also detected in diagnostics. However, there is a large proportion of people who convert this hydrogen into methane. If only hydrogen is measured in a breath analysis test, false-negative results can occur.

When such a disease is suspected, patients are often in the doctor's office for many hours in order to take several measurements of the exhaled breath after a test meal. Since metabolic processes also take place over a certain period of time, the course of the measurement curve is just as important as the absolute measured values. Due to the possibility of a continuous measurement with the LGD Compact, the metabolic process can be analyzed in resolution of seconds.

In addition to methane, the LGD Compact offers the possibility to measure CO2 as a second gas. Depending on the intensity of exhalation, the CO2 content and consequently also that of methane varies. Therefore, CO2 is used as a correction factor in the breath gas analysis. Due to the ability to tune the laser, several gases can often be measured if the spectral position of the gas peaks is good. Here, the Axetris LGD can provide an added value by eliminating the need for another sensor component for normalization.

Axetris puts micro-technology to work

Axetris serves OEM customers with micro technology (MEMS) based infrared light sources, laser gas sensors, gas flow sensors & controllers and micro-optical components used in industrial, telecom, environmental, medical and automotive applications.

Axetris is ISO 9001:2015 certified and operates 6-inch to 8-inch wafer MEMS cleanroom foundry for its own products and contract manufacturing for external customers. A wafer back end, a sensor assembly and calibration facility under clean room conditions completes the manufacturing infrastructure of Axetris.

Your OEM partner for gas sensing applications

The scalable broadband Infrared Source

Contact Information

Head of Global Sales: sanket.bhatia@axetris.com

Business Development Manager: melanie.wahlers@axetris.com

Axetris AG

Schwarzenbergstrasse 10

6056 Kaegiswil

Switzerland

The new LGD Compact combines TDLAS technology with a small and lightweight designed multipass cell and a modulation-based active noise reduction thanks to the unique optical laser package. Therefore, it is a perfect match for a wide range of portable instruments where performance and compact size matters.

Its over-all size of less than a can with a weight of 600 g allows for an easy integration. Due to the high selectivity, second gases can be measured at the same time without interference or confusion between the target gases. With these opportunities the new LGD Compact can be a perfect match for many gas measurement tasks.

Axetris IR sources are micro-machined, electrically modulated thermal infrared emitters featuring true black body radiation characteristics, low power consumption, high emissivity and a long lifetime. The appropriate design is based on a resistive heating element integrated onto a thin dielectric membrane which is suspended on a micro-machined silicon structure.

Axetris IR sources are ideally suited for advanced IR gas detection modules like non-dispersive infrared spectroscopy (NDIR), photoacoustic infrared spectroscopy (PAS) and attenuated-total-reflectance FTIR spectroscopy (ATR).

Because of the broadband emission, Axetris IR sources can be used for all IR-active Target gases such as CO, CO2, VOC, NOx, NH3, SOx, SF6, hydrocarbons, humidity, anesthetic agents, refrigerants, breath alcohols.

www.axetris.com/en/irs/products/emirs200