COMPANY

INSIGHT

NOTITLE

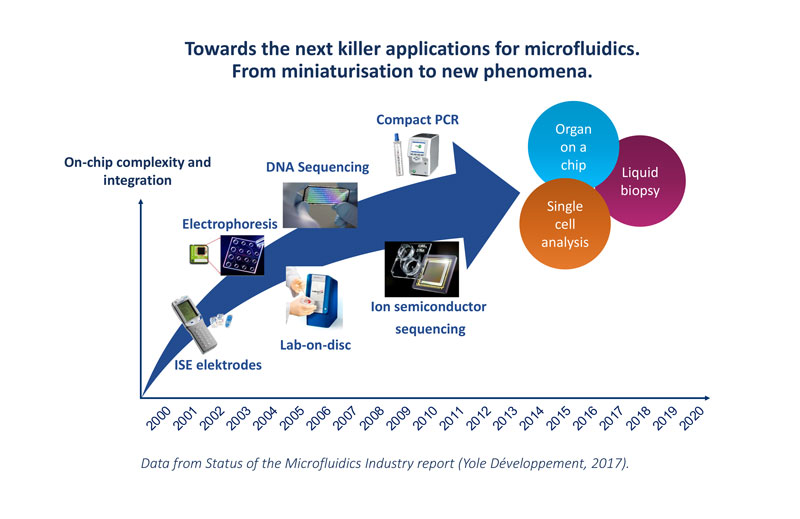

In the field of diagnostics, probably the most promising applications of microfluidics are in the field of oncology. As of today, most tests using microfluidics devices are targeting infectious diseases and chronic diseases (diabetes, cardiac conditions, kidney failure, psychiatric disorders), but few tests have been targeting cancer biomarkers as there are still few circulating blood or urinary biomarkers for cancer. This is where liquid biopsy combined with single cell analysis methods will play a major role in the next decade, bringing new tools to extract and analyse circulating cancer cells for diagnosis, prognosis and treatment monitoring. Approximately 40% of men and women will be diagnosed with cancer at some point in their lives [1], hence cancer is a rising concern in every country in the world - liquid biopsy and single cell analysis aim to add a new weapon to the arsenal of oncologists. However, liquid biopsy devices are very challenging to build because of the very precise microstructures required to sort circulating tumour cells (CTC). Indeed, new CTC selection methods are based on cell size and deformability. The challenge is huge, as microfluidic chips must enable rapid detection of one CTC among billions of blood cells. Several innovative designs are used to this end, from high and very thin micropillars (high aspect ratio structures) poised to slightly change larger cells’ trajectory within a microfluidic chamber [2], to inertial microfluidic chambers which trap CTC and allow other cells to flow out of the chamber (requiring very precise geometry, such as Vortex Biosciences’ technology).

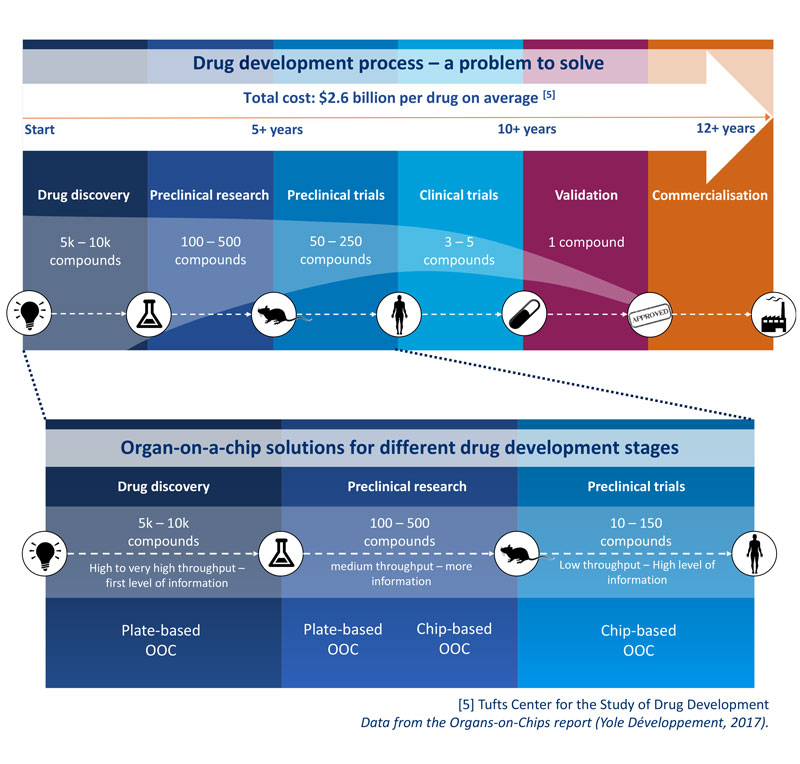

In the field of pharmaceutical research, organs-on-chips may change the current inefficient paradigm of the drug development process. An organ-on-a-chip is a combination of microtechnology and biology aimed at reconstituting the physiological and mechanical functions of human organs in the form of microengineered devices lined with living cells. Precisely controlled fluid flows combined with mechanical cues and tissue-tissue interfaces enable dynamic models that are expected to be much more relevant than conventional static cultures or animal models. These current methods are not predictive enough however, with about 90% of drugs validated on these models failing during clinical trials because of toxicity or lack of efficacy [3][4]. Indeed, bringing a new drug to the market takes about 12 years and costs several billion dollars. Organs-on-chips have the potential to address the colossal issues of delay and drug development cost, developing a new tool closer to human physiology.

Focus on technical and manufacturing capabilities

Such rapid and impressive progress in the field of diagnostics and medical device development can be explained by the direction taken by technology developers. Until recently, the focus was mainly on the miniaturisation of existing systems and processes found in laboratories, such as capillary electrophoresis and PCR, to enable parallelisation. Now the focus has switched to new developments thanks to process and materials innovation, with the emergence of totally new applications leveraging microfluidic technologies’ possibilities.

Such improvements significantly enhance medical device development. With innovative diagnostic tests, early detection of disease has now become a reality, paving the way for preventive actions and personalised medicine and leading to better health and higher life expectancy. Technology is helping clinicians in their daily activities, automating data handling and analysis and giving them more time to focus on their interaction with patients. Globally, systems are flexible, scalable and more efficient. Complex sample preparation can now be automated at a high throughput, allowing lab technicians to focus on other parts of the workflow such as data analysis.

OUR CUSTOMERS RANGE FROM INDIVIDUAL DOCTORS ALL THE WAY TO LARGE INTERNATIONAL MEDICAL DEVICE FIRM

These breakthroughs are only possible because of the progress that has been made by both top designers and top manufacturers. With the right capabilities and growing experience in the field, myriad possibilities are offered by microtechnology companies that may lead to improvements in healthcare.

OUR CUSTOMERS RANGE FROM INDIVIDUAL DOCTORS ALL THE WAY TO LARGE INTERNATIONAL MEDICAL DEVICE FIRM

Micronit

Micronit Microtechnologies B.V., founded in 1999, with development and manufacturing facilities in The Netherlands and Germany, provides innovative lab-on-a-chip and MEMS solutions using micro- and nanotechnologies. Solutions that help customers improve their products and research, contributing to the quality of life. Research & prototyping services, creative product development and quality manufacturing are its core businesses. Micronit is ISO 9001 and ISO 13485 certified.

References

[1] National Cancer Institute - Link

[2] Microfluidic Isolation of Circulating Tumor Cell Clusters by Size and Asymmetry. Sam H. Au et al. Sci Rep. 2017; 7: 2433

[3] Lost in translation: animal models and clinical trials in cancer treatment. Am J Transl Res, Isabella WY Mak, Nathan Evaniew, and Michelle Ghert 2014; 6(2): 114–118.

[4] Food for Thought Look Back in Anger – What Clinical Studies Tell Us About Preclinical Work. Thomas Hartung ALTEX, 2013; 30(3): 275–291.