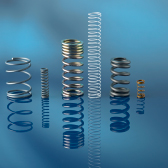

Bezinal® coated steel wires for use in medical applications

Meeting FDA and EFSA quality standards, Bezinal® XP and Bezinal® XC zinc-aluminum coated high carbon steel wires are an economical alternative to stainless steel for the production of medical springs in non-invasive surgical instruments such as in aerosols, inhalers, retractable syringes and dosing or auto-injector pens.

While Bezinal® XP excels in corrosion and cathodic protection, Bezinal® XC is characterized by a very stable coating integrity that can withstand heavy deformation without losing overall performance. Bezinal® XP and Bezinal® XC address several market demands like the increased need for miniaturization, prolonged shelf life and cost-efficient production.

Ideal for small, light and complex medical tools

Bezinal® XP and Bezinal® XC coated steel wires meet the growing need for smaller, lighter and more complex medical tools. The wires offer improved material properties over stainless steel the production of medical springs; Not only do they exhibit extended corrosion performance; they also demonstrate improved material properties including a 17% higher e-modulus and a higher maximum solid stress (+6% for non-stressed and up to +9% for pre-stressed springs) when applying standard designs. Moreover, it’s generally accepted that (pre-coated) high carbon wire solutions show better fatigue performance than stainless alternatives.

As a result, these wires allow you to:

meet tight tolerances

produce smaller spring dimensions

with higher spring rates

maintain high accuracy and repeatability

Easy to process, with low production costs

Unlike galvanized wires, Bezinal® XP and Bezinal® XC wires have very stable coatings layers. They create less flaking and dust during coiling and deformation, leading to much more cost-efficient production process:

creates a cleaner working environment

reduces frequency of machine cleaning

allows production at higher coiling speeds

eliminates the need for expensive post-coating processes

Read more about the process qualities of Bezinal® XP and Bezinal® XC in our whitepaper.

Prolonged shelf-life

Due to high corrosion resistance and cathodic protection ability, Bezinal® XP and Bezinal® XC are not susceptible to pitting corrosion and are capable of protecting defects for a prolonged time. Compared to galvanized or phospated wires, Bezinal® XC coated wires last about 10x longer and Bezinal® XP wires up to 20x longer, without additional post-coating.

Read more about the corrosion performance of Bezinal® XP (red and white rust protection and cathodic protection) in our whitepaper.

Bekaert - Your trusted supplier of medical steel wire

Bekaert is a world market and technology leader in steel wire transformation and coating technologies. To be the preferred supplier of steel wire products and solutions, we consistently deliver superior value to our customers worldwide. Bekaert was established in 1880 and is a global company with approximately 30000 employees worldwide. The company has worldwide production and storage facilities, customers in 120 countries, and cooperates closely with producers of medical tools. Choosing Bekaert as your partner means short lead times, on-time deliveries, consistent quality, and technical development and support.