Enabling our customers to make the best medical devices in the world

Machine Solutions is the premier provider of advanced equipment and services for the medical device industry. We support our customer needs and growth by delivering a wide breath of equipment solutions including stent crimping, balloon catheter pleating & folding, catheter testing, as well as innovative thermal forming technology for tipping and bonding of plastic tubing.

We believe in providing a superior customer experience by designating resources to a local team always ready to provide technical service and process support. Our recent investment in engineering services based in Europe show our commitment to developing long lasting, successful relationships with our European partners.

machinesolutions.com

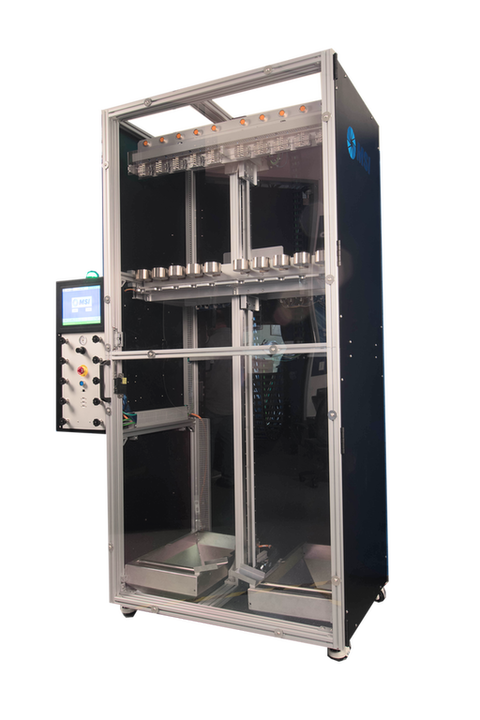

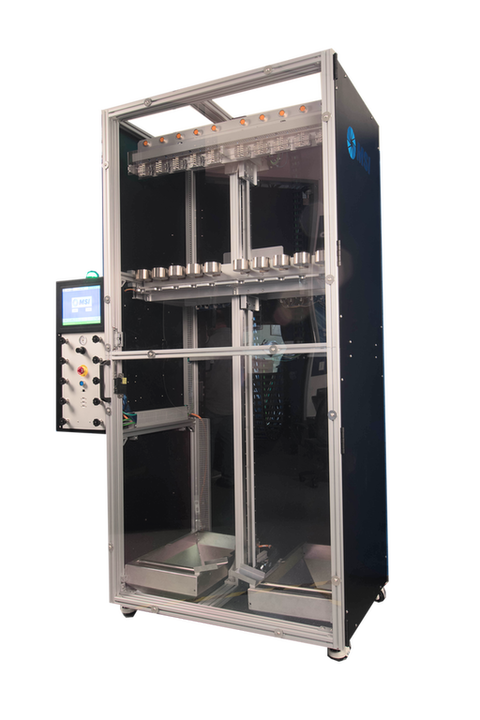

Automation platforms to improve productivity and performance

• Automated Workcell - Platform designed to improve the quality, speed

and cost of multiple balloon catheter and stent delivery product procsses

• Automated Ringbonder - Fully automated system for bonding drug eluting

medical plastics

• Multi-station catheter tipping platform- eliminates operator handling to

increase throughput

CONTACT US TO AUTOMATE

YOUR PROCESS!

Superior tipping technology

and services

Vante and PlasticWeld brands are recognized as global leaders, providing innovative production equipment for catheter and medical disposables manufacturers. Our platforms are recognized as industry leading technology for catheter tip forming, eye-forming, softtip bonding, butt welding, balloon bonding and hole drilling. The closed loop temperature control, small heat zones and embedded heating coils make our equipment robust, repeatable and able to accomplish applications that other technology cannot!

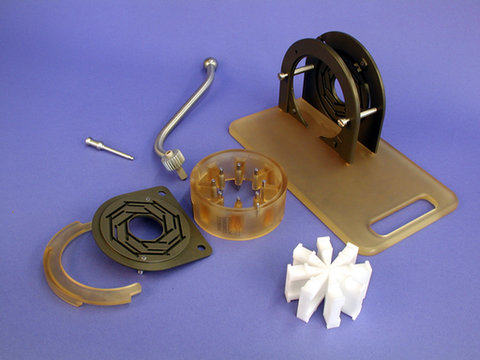

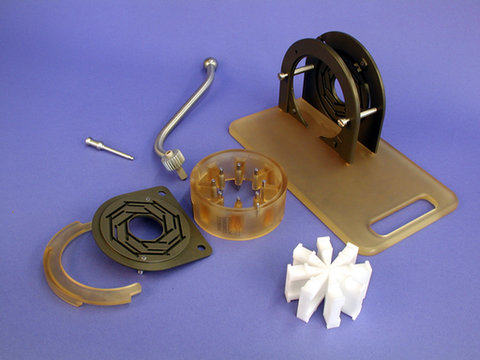

Certified tooling ready forvalidation and manufacture.

Medical device engineers need equipment that produce high quality products at high yields and are easy to validate. Our tooling certification service is the turnkey solution to meet this need!

We don’t just deliver metal hardware; our process delivers parts that meet your specification and support your validation activities. Our team of engineers certify over 300 tools annually and can apply their expertise to optimize your product.

Next Generation Catheter Laminating available now!

The next generation of catheter laminating is here, faster and more accurate than any other laminator. In both 4 up ad 10 up designes the VL1000 and VL400 produce more consistent lamination at twice the speed of previous models.

- Minimizes incidents of hot spots, bubbles and delamination

- Uniform air flow and temperature around the entire circumference of your product

- Adjustable height gripper rack for ergonomic product loading

- 0-34Fr product grippers and optional centering guides

- 175, 205 or 255cm travel length options

- Profiles can be saved and recalled as needed, easy set up and providing a repeatable process.

- Optional system for constant tension of heat shrink

Local Service And Support

Machine Solutions companis have a dedicated service and support team with engineering experts ready to maintaine your equipment.

Repairs, Upgrades, and Regular Maintinance can be done at your facility, reducing downtime.

Engineering Experts for your application

Free assessment of your application by our engineering team with 5,000+ mold design experience

Our engagement model enables you to quickly produce your products to desired specifications

Mold certification process ensures your part dimensions being produced repeatably

Rapid prototype value stream that can make custom tooling for engineering samples in less than 2 weeks

Equipment is designed to integrate into automation platforms

4 Manufacturing Facilities with in-house EDM, 5 Axis CNC and multiple certified mold producers

Whether you are a start-up company looking to test your first prototypes or need production volumes of 10,000+ units annually, we can provide the perfect solution for your bedside crimping application.

- Designed for crimping balloon expandable and self-expanding heart valves in a lab and at patient bedside.

- Durable base unit configurations capable of withstanding auto-clave cleaning.

- Single use disposable units for ETO sterilization processes.

- Custom configurations and design consultation.

CONTACT US

Enabling our customers to make the best medical devices in the world

Machine Solutions is the premier provider of advanced equipment and services for the medical device industry. We support our customer needs and growth by delivering a wide breath of equipment solutions including stent crimping, balloon catheter pleating & folding, catheter testing, as well as innovative thermal forming technology for tipping and bonding of plastic tubing.

We believe in providing a superior customer experience by designating resources to a local team always ready to provide technical service and process support. Our recent investment in engineering services based in Europe show our commitment to developing long lasting, successful relationships with our European partners.

machinesolutions.com

Automation platforms to improve productivity and performance

• Automated Workcell - Platform

designed to improve the quality,

speed and cost of multiple balloon

catheter and stent delivery product

procsses

• Automated Ringbonder - Fully

automated system for bonding drug

eluting medical plastics

• Multi-station catheter tipping platform-

eliminates operator handling

to increase throughput

CONTACT US TO AUTOMATE

YOUR PROCESS!

Superior tipping technology and services

Vante and PlasticWeld brands are recognized as global leaders, providing innovative production equipment for catheter and medical disposables manufacturers. Our platforms are recognized as industry leading technology for catheter tip forming, eye-forming, softtip bonding, butt welding, balloon bonding and hole drilling. The closed loop temperature control, small heat zones and embedded heating coils make our equipment robust, repeatable and able to accomplish applications that other technology cannot!

Certified tooling ready forvalidation and manufacture.

Medical device engineers need equipment that produce high quality products at high yields and are easy to validate. Our tooling certification service is the turnkey solution to meet this need!

We don’t just deliver metal hardware; our process delivers parts that meet your specification and support your validation activities. Our team of engineers certify over 300 tools annually and can apply their expertise to optimize your product.

Next Generation Catheter Laminating available now!

The next generation of catheter laminating is here, faster and more accurate than any other laminator. In both 4 up ad 10 up designes the VL1000 and VL400 produce more consistent lamination at twice the speed of previous models.

- Minimizes incidents of hot spots, bubbles and delamination

- Uniform air flow and temperature around the entire circumference of your product

- Adjustable height gripper rack for ergonomic product loading

- 0-34Fr product grippers and optional centering guides

- 175, 205 or 255cm travel length options

- Profiles can be saved and recalled as needed, easy set up and providing a repeatable process.

- Optional system for constant tension of heat shrink

Local Service And Support

Machine Solutions companis have a dedicated service and support team with engineering experts ready to maintaine your equipment.

Repairs, Upgrades, and Regular Maintinance can be done at your facility, reducing downtime.

Engineering Experts for your application

Free assessment of your application by our engineering team with 5,000+ mold design experience

Our engagement model enables you to quickly produce your products to desired specifications

Mold certification process ensures your part dimensions being produced repeatably

Rapid prototype value stream that can make custom tooling for engineering samples in less than 2 weeks

Equipment is designed to integrate into automation platforms

4 Manufacturing Facilities with in-house EDM, 5 Axis CNC and multiple certified mold producers

Whether you are a start-up company looking to test your first prototypes or need production volumes of 10,000+ units annually, we can provide the perfect solution for your bedside crimping application.

- Designed for crimping balloon expandable and self-expanding heart valves in a lab and at patient bedside.

- Durable base unit configurations capable of withstanding auto-clave cleaning.

- Single use disposable units for ETO sterilization processes.

- Custom configurations and design consultation.

CONTACT US