COMPANY

INSIGHT

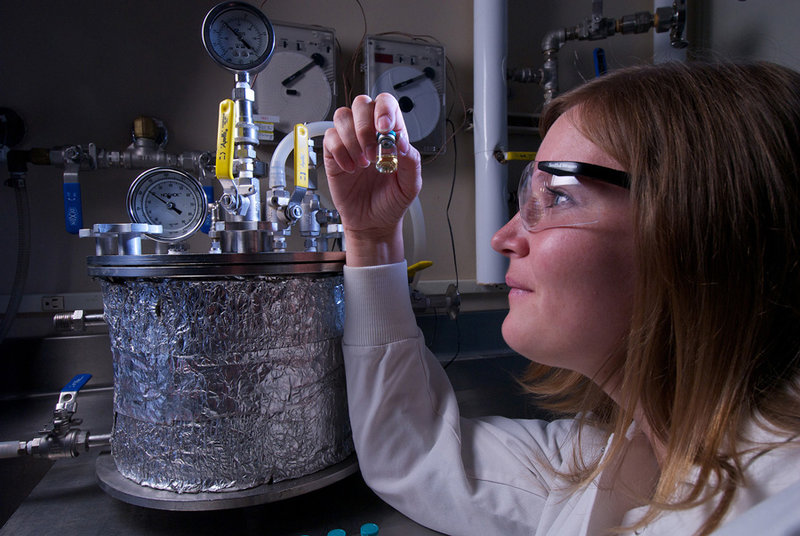

Nelson Laboratories

We share a proud history with those in the medical device industry as we have tested many of the innovative medical products on the market today to ensure they perform safely and effectively. With the enactment of the U.S. Federal Food, Drug, and Cosmetic Act (FD&C Act) of 1938, the U.S. government began their oversight of medical devices. Subsequently, U.S. Congress chartered the Cooper Committee to take inventory of all medical devices currently in use. Following that review, the 1976 Medical Device Amendments were passed giving authority to the U.S. FDA to regulate medical devices. This dramatically altered the medical device industry and ultimately gave rise to Nelson Laboratories.

The following are a few of the key medical applications where ElectroCraft motors empower medical motion control.

Why Choose Nelson Laboratories

Every year, hundreds of medical device, pharmaceutical, and tissue companies make Nelson Labs their testing laboratory of choice. For them, the decision is easy. Nelson Labs is a clear leader in the microbiology testing industry, offering more than 400 laboratory tests and employing more than700 scientists and staff in state-of-the-art facilities. We are known for exceptional quality and rigorous testing standards, but it’s our focus on the bigger picture that sets us apart. We look beyond test results and partner with you to achieve your long-term business goals — mitigating risk, being first to market, and succeeding with your customers.

Companies choose Nelson Laboratories for our:

- Thought leaders and approachable experts. We give you direct access to industry authorities who understand your business and add value every step of the way.

- Customer-centric culture. We take the time to understand your vision. Your goals become our goals.

- Real-time project management tools and a dedicated client portal. We provide proactive information, keeping you informed and in control.

- Metric-driven testing processes. We're our own toughest customer, holding ourselves to goals exceeding 99% for things that matter most to you, like quality, turn-around time, and testing accuracy.

- Global compliance expertise and support. We act as a trusted advisor, helping you navigate the ever-changing compliance landscape.

See how we can help you mitigate risk, be first to market, and succeed with your customers.

Biocompatibility & Toxicology

Nelson Labs offers a full trifecta of services to meet the requirements of ISO 10993 for Extractables&Leachables, Biocompatibility and Toxicological Assessments of medical devices. Biocompatibility testing is very common in the medical device industry. However, with 24 possible categories, each with a unique set of testing requirements, the biocompatibility testing experience can be intimidating. Even after a device has been categorized, a myriad of decisions for each test remains.

Generally we recommend customers perform the following for new products:

- Biological Evaluation Plan (BEP)

- Product Tests – Biocompatibility (in vivo, in vitro) and Chemistry (E&L)

- Toxicological Assessment – Data summary and qualified safety assessment

The biocompatibility team at Nelson Laboratories will work with you to develop a comprehensive testing plan that’s right for your product. We will also partner with you throughout the testing process, helping you to eliminate time- and resource-draining surprises.

Extractables & Leachables

Nelson Labs Europe offers a comprehensive approach towards Extractables / Leachables testing for the pharmaceutical industry. Our approach combines a technical and analytical expertise, polymer knowledge, understanding of regulatory requirements, all combined in a tailored approach to our customers.

Extractables&Leachables test services include:

- E&L for Medical Devices

- E&L for Pharmaceutical Containers

- Impurities in Drug Components & APIs

- Material Characterization Screens for Raw Materials

- Physiochemical USP Plastics Tests

Sterilization Validations

Nelson Labs offers unparalleled expertise in product sterilization validations across a broad range of technologies. With the combined resources and expertise of Nelson Labs and Sterigenics, our understanding of material compatibility, sterilization science, validation approaches and cycle optimization ensure customers have a reliable, defensible validation strategy.

Sterilization Validation services offered include:

- Clinical Batch Release

- Exposure & Repeat Exposure Cycles

- Filter Sterilization Validations

- Product Inoculations

- Sterilization Resistance Studies

- Sterilization Supplies (BIs & PCDs)

- Sterilization Validations – EO

- Sterilization Validations – Radiation

- Thermal Disinfection

Sterility Assurance

Nelson Labs is a leading provider of sterility assurance test services for medical device, pharmaceutical, and tissue manufacturers for both sterile and non-sterile products. Most tests follow United States or European Pharmacopeia (USP or EP) and similar international standards. For sterilized medical devices standards are also found in ISO, AAMI and ASTM guidance documents.

Packaging Solutions

We offer unparalleled breadth of packaging experience to help our clients deliver safe and effective products to market. Our services encompass consulting, package validation, material qualification, and package development.

Nelson Labs packaging solutions department has experience with successful validations encompassing multiple product, package, and sterilization configurations throughout the medical and pharmaceutical industries. We use proven state-of-the-art technology to provide fast and accurate results.

Packaging test solutions for the pharmaceutical industry include:

- Accelerated & Real Time Aging

- Container Closure Integrity – Dye Immersion

- Container Closure Integrity – Mass Extraction

- Integrity & Strength Tests

- Stability Studies – Pharmaceutical

- Thermal Cycling Studies

- Transportation and Distribution Performance

- Whole Package Integrity Tests

Applied Harmonics:

These are just a sampling of the applications that ElectroCraft provides motion control solutions for in the medical market, and only a hint at future innovation. As a custom motor and motion control solution provider, ElectroCraft is the ideal partner for your medical equipment requirements.

Clinical Reprocessing Validations

Nelson Laboratories offers a full range of medical device cleaning, disinfection and sterilization validation services to validate manufacturers’ cleaning instructions for reusable devices. This is essential to ensuring that medical devices reprocessed in a healthcare setting are safe for their intended use or reuse.

Medical device manufacturers should validate end of life cycles for reusable or reprocessed medical devices to demonstrate functionality with repeated exposures and clinical simulations.

In addition, reusing single-use devices that have been safely reprocessed by a third-party reprocessor can enable healthcare providers to maintain high-quality patient care while saving on costs and reducing medical waste. Validated functionality testing must be paired with validated cleaning, disinfection, and sterilization processes to ensure safety and compliance of regulatory requirements for third-party reprocessing.