IMPLANT COATING SERVICE

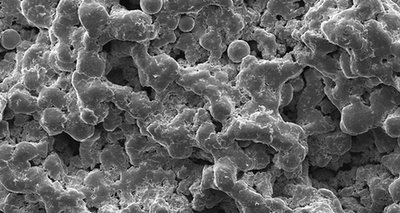

POROUS TITANIUM COATINGS BY THERMAL SPRAY PROCESS

Porous Titanium coatings to provide strong bone anchorage, excellent primary and secondary osseointegration on acetabular cups, femoral stems, tibial or femoral knee replacement components.

Coating and raw material characteritics fulfilling ISO 13179-1:2014, ASTM F 1580-12 and CDRH Guidance for Industry on the Testing of Metallic Plasma Sprayed Coatings on Orthopedic Implants

ROUGH HYDROXYAPATITE COATINGS BY THERMAL SPRAY PROCESS

Highly biocompatible osseointegrative calcium phosphate coating of crystalline hydroxyapatite to provide rapid secondary integration of orthopedics implants

Coating and raw material characteritics fulfilling ISO 13779-2:2018, ISO 13779-3:2018, ISO 13779-4:2018, ISO 13779-6:2015

COMPLETE COATING OF COMPLEX SPINAL IMPLANTS

Rough Titanium coating of complex shape spinal implants like intervertebral spacers or pedicle screws made of PEEK or Carbon-Reinforced PEEK

Protecting mechanical properties of base material, ensuring high adhesion strength

DIRECT COATING OF CERAMIC IMPLANT

Dual Titanium and Hydroxyapatite coating of ceramic implants without preliminary surface roughening

Allowing new implant design, removing need of metallic cases, removing risk of embrittlement due to abrasive grit blasting

THERMAL SPRAY COATING EQUIPMENT

VACUUM PLASMA SPRAY – VPS

Coating equipment based on the technology developped by Medicoat made available to implant legal manufacturers, contract manufacturers and coating service providers

Highly efficient coating process integrated with complex robotics system, modern human machine interface and in-process monitoring

ATMOSPHERIC PLASMA SPRAY – APS

Coating equipment based on the technology developped by Medicoat is made available to implant manufacturers, contract manufacturers, coating service providers

SPRAY POWDER PRODUCTION

HYDROXYAPATITE POWDERS

Own production of medical grade hydroxyapatite powders for thermal spray coating and for resorbable media blasting (RBM). Both sintered crushed and spray dried powders in various grain sizes available.

Characteristics of hydroxyapatite spray powders fulfilling ISO 13779-6:2015 requirements. Highly skilled research team for customer specific powder optimization.

TITANIUM POWDERS

Production of Titanium powders from fine to coarse particles for APS and VPS thermal spray processes.

Characteristics of titanium spray powders fulfilling ASTM F 1580-12 requirements.

IMPLANT MANUFACTURING AND CLEAN ROOM PACKAGING

Machining shop for implants like femoral stems or acetabular cups, including laser marking, polishing and passivation. The facility is certified ISO 13485 has been audited by several authorities (USA FDA, Brazil ANVISA, Korea MFDS)

Final packaging in clean rooms class ISO 6 of orthopedic implants in double pouches or blister.

Research and development

MATERIAL TESTING LABORATORY

Extensive material testing capability for powder and coating characterization (quantitative analysis by X-Ray Diffraction), optical microscopy, static adhesion testing and abrasion testing.

PROCESS ENGINEERING

Development of customer specific coating by thermal spray processes.

On site engineering support for process optimization, robotics, servicing and calibration